The aluminum chequered sheet and the GI perforated sheet are sheets that stand out with regard to robust and flexible materials utilized in construction, engineering, and manufacturing. Because of their precise characteristics, flexibility, and long-lasting energy, those materials are used in many different industries. The aluminum chequered sheet is extraordinary for conditions in which you want a floor that is lightweight and robust. The GI perforated sheet is superb for conditions in which air flow, filtering, or drainage are critical.

What is an Aluminium Chequered Sheet? What is it used for?

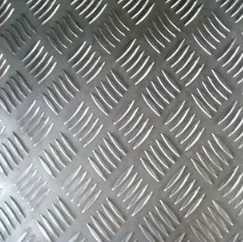

People love Aluminium Chequered Sheet because they are sturdy, light, and feature a unique layout. The sheets are built of exquisite aluminum, which is a massive plus in industries where decreasing weight is vital without dropping strength. Here are some essential functions and makes uses:

- Lightweight and Strong: Aluminum is a great material for things that need to be strong but not too heavy because it is so light.

- Aluminum is naturally resistant to corrosion, especially in severe situations like maritime applications or places with high humidity.

- The checkered pattern not only looks nice, but it also improves grip, which is why it is a favorite choice for ramps and flooring.

People on occasion lease aluminum chequered sheets for:

- Flooring: For ramps, steps, and pathways that might not slip.

- Vehicle Construction: For making vehicles, trailers, and distinct automobiles that need strong, moderate-weight materials.

- Storage Solutions: Used to make shelves, storage racks, and exceptional business organization systems, wherein energy and weight are important.

GI Perforated Sheet: A Flexible Answer

Another essential cloth that is beneficial for industries that need accuracy and electricity is GI (Galvanized Iron) perforated sheets. To make those sheets, galvanized iron is perforated to make holes of specially sizes, shapes, and styles. This allows them to do plenty of various things, in conjunction with clean out the air and permitting it to go with the waft. Some important developments are:

- High Strength and Durability: Galvanized iron is pretty strong; consequently, GI perforated sheets can control tough situations without losing their structural integrity.

- Versatile Design: GI perforated sheets are outstanding for lots of one of a kind makes uses, from decorative to commercial, because of the truth you can change the dimensions and design of the holes.

- Corrosion Resistance: Like the aluminum chequered sheet, GI perforated sheet do not rust or corrode, in order that they ultimate longer when they’re outside.

GI perforated sheets are utilized in:

- Architectural Uses: Used a lot in constructing facades and external panels for each appears and function.

- Industrial Filtration: Great to be used in any sort of filtration gadget, like air, water, or other commercial operations.

- GI perforated sheets are often used to growth the sound quality in locations like theaters and auditoriums by making them better at absorbing sound.

Aluminum chequered sheets and GI perforated sheets are different.

Knowing the main distinctions between the two materials might help you choose the correct one for the project, even though both have their own benefits. Here is a quick look at the differences:

- Weight: Aluminium chequered sheets are lighter than GI perforated sheets, hence they are better for uses where weight is important.

- Strength: GI perforated sheets are usually stronger than aluminum, which makes them great for heavy-duty industrial uses.

- Resistance to the Elements: Both materials are quite resistant to corrosion, although aluminum is preferable for places that are more corrosive, like the ocean.

Why Should You Use These Sheets for Your Project?

It may not be easy to select an appropriate material for a task; however, the aluminium chequered sheet and GI perforated sheet have special benefits that make them exceptional for varied uses. These sheets can provide you with the right blend of energy, software, and layout flexibility for any task, whether it is building something or developing with a particular engineering answer. These materials are very useful in many fields since they can be changed and tailored to meet specific needs.

Conclusion

These materials are the best because they are both reliable and efficient. If you want to get the most out of your building and design projects, materials like the aluminum chequered sheet and GI perforated sheet are great choices. Visit Dinco.ae to learn more about the best metal sheet options.

FAQs

- What is the primary advantage of aluminium chequered sheets over other materials?

Aluminium chequered sheets are lightweight, corrosion-resistant, and offer an anti-slip surface, making them ideal for flooring, ramps, and vehicle construction.

2. Can GI perforated sheets be used in outdoor applications?

Yes, GI perforated sheets are ideal for outdoor use as they are made of galvanized iron, which offers excellent resistance to corrosion and harsh weather conditions.

3. Are there different hole patterns available in GI perforated sheets?

Yes, GI perforated sheets can be customized with various hole patterns, sizes, and shapes to meet specific needs, such as filtration, ventilation, or aesthetic purposes.

4. What industries commonly use aluminium chequered sheets?

Aluminium chequered sheets are commonly used in automotive, construction, and marine industries for their strength, light weight, and non-slip surface properties.

5. How does the strength of GI perforated sheets compare to other metal sheets?

GI perforated sheets are stronger than many other metal sheets, making them ideal for heavy-duty applications like industrial filtration, architecture, and acoustic panels.